Frequently Asked Questions (FAQs) – Custom Food Packaging Boxes

1. How much does it cost to make custom food packaging?

The cost of custom food packaging boxes depends on several factors, including:

Material type (kraft, cardboard, corrugated, or paperboard)

Box size and structure

Printing method (CMYK, PMS, foil, or digital)

Quantity ordered

On average, small businesses can expect to spend $0.35 – $1.50 per box, depending on design complexity and volume.

From our experience working with cafés and bakeries, bulk orders (above 1,000 units) can reduce per-unit costs by up to 40%, making custom packaging surprisingly affordable.

-Pro Tip: Start with a pilot batch to test material quality and design appeal before scaling production.

2. How to create custom food packaging for your brand?

Designing your own custom food packaging involves a few simple but crucial steps:

Step 1 – Define your product needs:

Identify whether you’re packaging hot food, bakery items, beverages, or dry goods. Each category needs a different material type (e.g., grease-resistant for fries, airtight for coffee).

Step 2 – Choose material and structure:

Select food-grade materials like kraft or corrugated board for durability and sustainability. Decide on the box shape — tuck end, clamshell, or sleeve.

Step 3 – Add your branding:

Use professional CMYK printing and finishes like matte lamination or foil stamping for a premium look. Include your logo, tagline, and colors to enhance recognition.

Step 4 – Approve a prototype:

Request a sample to test print quality, coating, and overall presentation.

Step 5 – Order & distribute:

Finalize production, ensuring packaging aligns with FDA and food-grade standards.

–From experience: Many restaurant clients found that consistent branded packaging helped improve online reviews and repeat orders — presentation truly impacts perception.

3. What is the meaning of custom food packaging?

Custom food packaging means creating packaging that’s specifically designed for your brand and product instead of using generic or plain boxes.

It allows you to:

Select exact dimensions to fit your food perfectly.

Add custom designs, colors, and branding to reflect your identity.

Utilize eco-friendly and food-safe materials specifically designed for your business.

In simple terms, it’s packaging built for your product and your brand story, not one-size-fits-all.

Restaurants and bakeries using personalized packaging often experience a 20–30% boost in customer recall compared to non-branded boxes.

4. What are the three main types of food packaging?

There are many types, but generally, food packaging can be grouped into three key categories:

1. Primary Packaging:

Directly contacts the food (e.g., burger wraps, bakery boxes, tea or coffee boxes). It must be food-grade, hygienic, and moisture-resistant.

2. Secondary Packaging:

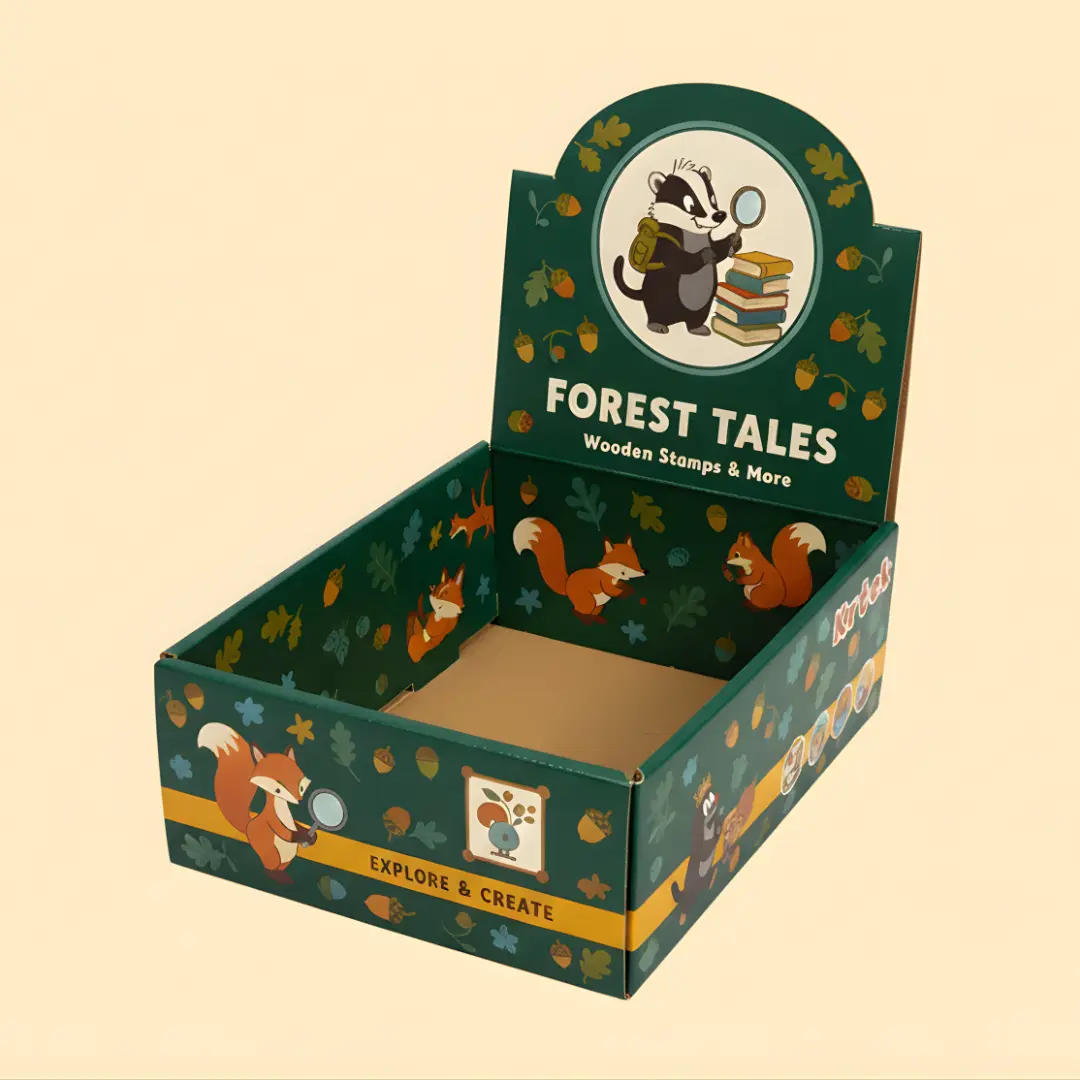

Used for branding or grouping multiple primary packs — like custom printed boxes for takeout or gift sets.

3. Tertiary Packaging:

Meant for transport and bulk handling, such as corrugated cartons for shipping food boxes safely.

At Packaging Squad, we ensure each layer serves both protection and presentation, especially for delivery-based food businesses.

5. What materials are best for custom food packaging?

Based on our experience with hundreds of restaurant and bakery clients, the best materials depend on your food type and branding goals:

Kraft Paper: Eco-friendly, rustic, and ideal for fast-food or organic brands.

Cardboard / Paperboard: Lightweight yet strong; perfect for cakes, coffee, and candy boxes.

Corrugated Board: High durability and insulation for hot or heavy meals.

Recyclable Coated Paper: Smooth surface for high-quality printing and grease resistance.

-Pro Tip: Use a matte finish for a premium look and gloss finish for colorful, vibrant designs.

6. Why should I invest in eco-friendly food packaging?

Sustainability isn’t just a trend — it’s a brand value. Research shows that 61% of consumers are more likely to buy from brands using recyclable or compostable packaging.

Eco-friendly custom food packaging not only helps reduce waste but also builds customer trust and positions your business as environmentally responsible.

Plus, sustainable materials like kraft and biodegradable board still offer excellent strength, freshness, and print clarity.

–From our experience: Restaurants switching to kraft boxes reported positive feedback and social media mentions from eco-conscious customers.

7. How can custom packaging improve my food delivery experience?

Custom packaging is one of the most overlooked ways to improve delivery satisfaction.

Sturdy boxes prevent spillage and damage during transit.

Branded packaging reassures customers of hygiene and quality.

Right-fit boxes reduce air space, keeping food hotter and fresher.

For example, using a custom burger box with an anti-grease lining can keep fries and burgers intact for up to 30 minutes longer during delivery.

8. Can I order small quantities of custom food packaging?

Absolutely! Our Minimum Order Quantity (MOQ) starts as low as 100 boxes, making it easy for startups, food trucks, and small cafés to get started without high upfront costs.

You can also test multiple designs before scaling — a strategy many successful restaurant owners use to find their perfect brand look.

Sed risus neque, sagittis sed pellente sque at, pharetra ut nunc. Phasellus id enim eget ante pellentesque pharetra. Phasellus et nisl urna. Integer nisl dui, efficitur in vopat sodales, tempor sed orci. Donec et euismod ipsum. Interdum et malesuada fames ac ante ipsum primis in faucibus.